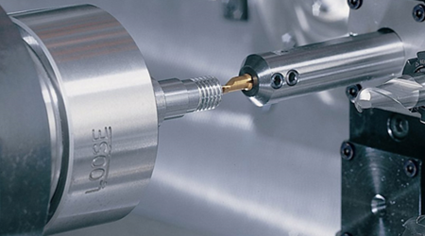

These for special

applications developed systems are suited in particular for the supply of

drills with inner cooling with an adverse diameter-length- rate.

More...

Flat band conveyors to

transport chips and small parts. Two chain strands (roller chains) which have

been connected to make up a hinge band by means of steel plates with side

boards, continuously convey the material to be conveyed, situated on the

conveyor belt, to the discharge station.

More...

With the option Y2-Axis

you’ll have the possibility to tip the backside working system with 9 tools.

More...

Due to higher cutting rates and the rapid development of high tech machinery/tooling, the danger of a fire occurring during fully automated machining has been increasing considerably.

Due to the modular layout of our ML-Pro Line, you can choose a variety of tool holders:

Evacuation of long parts is generally carried out by pushing the part through the sub spindle:

For long parts it is required to use a part extractor and a parts tray. We offer you the following types:

Amplified sub spindle:

More output power and higher torque define the option of an, “amplified sub spindle”.

Available on all Maier machines except Series F4, the “Hybrid” spindle allows the operator the flexibility to remove the guide bushing unit and synchronization, typical to all “Swiss type” machines, when shorter components are to be machined.

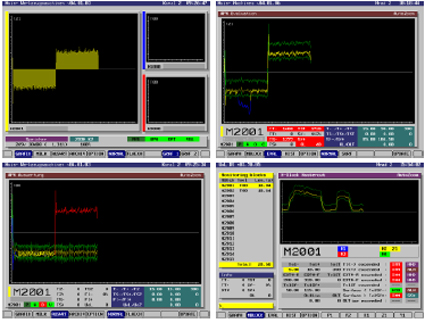

The Maier tools process monitoring systems controls the liftetime of the cutting tools. It can also control several chapeters in a cnc program. This system increases the safety operation in case of high tool wear , especially at unmanned shift.